Alles über magnetische Abschirmung

Eine magnetische Abschirmung dient also dazu, ein Instrument vor diesem Magnetfeld zu schützen, damit es optimal funktioniert, oder eine Umgebung vor einem Magnetfeld zu schützen, das von einem Instrument und/oder einer Energiequelle ausgeht. Ebenso kann ein Instrument selbst ein Magnetfeld ausstrahlen, das starke Interferenzen mit elektrischen Geräten verursachen kann. Wenn die Geräte nicht abgeschirmt sind, kann der magnetische Fluss den Betrieb stören.

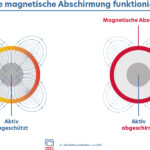

Es gibt zwei Arten der magnetischen Abschirmung, die sich gegenseitig ergänzen:

- die passive Abschirmung

die aktive Abschirmung

Bei der passiven Abschirmung (Kernkompetenz von MECA MAGNETIC) kann das Magnetfeld von einem Metallschild absorbiert werden.

Bei einer aktiven Abschirmung kann das Magnetfeld auch durch ein anderes Instrument neutralisiert werden, das ein entgegengesetztes Magnetfeld mit gleichem Wert aussendet, wodurch in einem begrenzten Raum das Restfeld unterdrückt wird. Das Know-how einer Abschirmung besteht darin, eine dieser beiden Lösungen auszuwählen und manchmal auch beide zu kombinieren, wenn der Bedarf an Restfeld in einem Raum sehr gering ist, was eine Kompetenz von MECA MAGNETIC ist.

Eine passive magnetische Abschirmung kann als Faradayscher Käfig für magnetische Gleichfelder oder niederfrequente Magnetfelder betrachtet werden. Im Unterschied zum Faradayschen Käfig wird versucht, ein Feld daran zu hindern, in ein Volumen einzutreten oder es zu verlassen, oder es in einem bestimmten Volumen zu kanalisieren.

Nur bestimmte Materialien haben eine hohe magnetische Permeabilität oder magnetische Suszeptibilität und eine geringe Koerzitivfeldstärke (Begrenzung Hysterese-Effekte, nämlich Permimphy oder andere Eisen-Nickel-Legierungen. Ein Material mit einer hohen magnetischen Suszeptibilität neigt dazu, die magnetischen Feldlinien zu bündeln.

Das Prinzip der passiven Abschirmung

Eine magnetische Abschirmung ist eine mechanische Lösung, meist aus einem Blechteil, die dazu dient, ein Problem mit niederfrequenten elektromagnetischen Störungen zu lösen. Man spricht in diesem Fall von passiver Abschirmung.

Eine Abschirmung leitet die magnetische Komponente der elektromagnetischen Welle in einem Frequenzbereich von 0,1 bis 10 000 Hz. Oberhalb von 10 000 Hz werden elektrische Abschirmungen verwendet, die aus anderen Materialien hergestellt werden und andere Designs erfordern.

- Der Zweck einer Abschirmung ist es, die magnetischen Feldlinien anzuziehen, zu bündeln und abzulenken. Auf diese Weise kann verhindert werden, dass sie in ein bestimmtes Volumen gelangen (z. B. die Abschirmung einer Bildröhre), oder es kann verhindert werden, dass sich ein Magnetfeld ausbreitet (z. B. die Abschirmung eines Transformators).

Eine Feldlinie lässt sich nicht speichern, nicht anhalten und immer wieder neu schließen. Sie breitet sich in dem Medium aus, in dem die Permeabilität am größten ist.

Anders als bei der elektrischen Abschirmung geht es bei der magnetischen Abschirmung darum, die Feldlinien abzulenken, sodass eine einfache Platte eine Abschirmung darstellt.

Eine magnetische Abschirmung entwerfen

Die Überprüfung des Gebrauchs

Bevor Sie sich auf die Suche nach einer Lösung machen, sollten Sie folgende Punkte überprüfen:

- – Befinde ich mich in einem Gleichfeld oder einem Wechselfeld?

– Habe ich es mit einem schwachen oder einem starken Feld zu tun?

– Muss ich die Verschmutzung oder den empfindlichen Teil abschirmen?

– Welche Dämpfung muss ich haben?

- – Sind die angegebenen oder gemessenen Werte zuverlässig?

– Werden diese Werte als Mittelwerte oder als Spitzenwerte angegeben?

– Wie viel Platz habe ich, um eine Abschirmung anzubringen?

– Welche Parameter muss ich außerdem berücksichtigen: Belüftung, Kabeldurchführung, mechanische oder klimatische Beanspruchung, Zugänglichkeit?

Die Entwurfsmethoden

Es gibt verschiedene Entwurfsmethoden:

– Ausgehend von recht einfachen Formeln, die im Gleichfeld sehr schnell eine Vorstellung von der Lösung vermitteln können.

– Ausgehend von etwas komplexeren Formeln (unter Verwendung von Abakus), die unter anderem von Albrecht J. MAGER 1970 formalisiert wurden, der ausgehend von einfachen Formen Lösungen im Gleich- oder Wechselstrombereich verfeinert.

– Ausgehend von Finite-Elemente-Simulationen (unter Einbeziehung der Maxwell-Gleichungen ); diese Lösung bleibt ein Ansatz für komplexe Formen und hängt stark von der Vernetzung und den B-H-Kurven der Materialien ab, die in die Software integriert sind.

- – Anhand des Designs und des Dämpfungsbedarfs kann ein möglicher zusätzlicher Bedarf an aktiver Abschirmung ermittelt werden.

Welches Material für welches Abschirmungsergebnis?

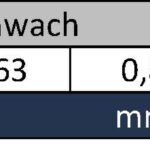

Die bearbeiteten Dicken

Einlagig versus mehrlagig

Die geforderte Magnetfelddämpfung ist eines der Kriterien für die Wahl der Dicke des gewählten Materials und die Entscheidung zwischen Monolayer und Multilayer. Das zweite Kriterium ist die Belastung durch die abzuschirmende Oberfläche und/oder die geforderte Restfläche.

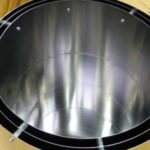

- Ein Multilayer ist ein spezifisches Know-how, das bei MECA MAGNETIC beherrscht wird. Sie besteht aus einer Folge von Abschirmungen, die nach dem Prinzip der russischen Puppen zusammengesetzt werden. Man geht davon aus, dass zwei 1 mm dicke Schichten, die durch einen Luftspalt getrennt sind, wirksamer sind als eine 2 mm dicke Schicht (Analogie zur Doppelverglasung).

Man verwendet es, wenn die Felder hoch sind oder wenn man eine hohe Dämpfung anstrebt. Schicht für Schicht sinken die Feldstärken sehr stark. So können Sättigungserscheinungen vermieden und extrem niedrige Restfeldstärken erreicht werden. Dies ist die ideale Lösung für Nullfeldkammern. Im Vergleich zum Erdfeld werden Dämpfungen um den Faktor 10 000 erreicht, was Restfelder von einigen Nano-Tesla ermöglicht.

Die geltenden Vorschriften

Im Juni 2013 wurde eine EU-Richtlinie zu elektromagnetischen Feldern verabschiedet: 2013/35/EU

Jedes europäische Land kann auf nationaler Ebene strengere Vorschriften als diese europäische Verordnung haben. Dies ist zum Beispiel in Frankreich mit dem Dekret Nr. 2013-1162 der Fall, das einen strengeren Rahmen für bestimmte sensible Umgebungen (Krankenhäuser, Schulen…) festlegt.

FAQ

Ein Magnetfeld ist ein physikalisches Phänomen, das durch die Bewegung von elektrischen Ladungen entsteht und durch magnetische Materialien offenbart wird.

Um den Mechanismus vom Magnetfeld des Magneten zu isolieren, muss man entweder den Magneten in einem FARADAY-Käfig einschließen oder den Mechanismus darin einschließen.

Das Magnetfeld durchdringt alles, Trennwände, Beton, Granit, den menschlichen Körper … und kann nicht aufgehalten werden. Die einzige Möglichkeit, sich davor zu schützen, besteht darin, sich von der Quelle zu entfernen.

Ja, eine magnetische Abschirmung ist möglich, wenn man Materialien mit hoher magnetischer Suszeptibilität verwendet, die die magnetischen Feldlinien so bündeln, dass sie innerhalb des Materials bleiben.

Durch die Verwendung eines Materials, das in der Lage ist, Magnetfeldlinien zu bündeln, die im Raum von Magnetfeldquellen wie Magneten erzeugt werden.

Es ist eine Abschirmung gegen magnetische Wellen, die in einem definierten Volumen das umgebende Magnetfeld dämpft.

Beides ist möglich. Entweder soll ein empfindliches Element nicht gestört werden, oder ein Element soll nicht stören.

Wie weit kann man abschirmen (Frequenz und Leistung)?

Man kann jede Frequenz nach verschiedenen Techniken abschirmen. Bei niedrigen Frequenzen verwendet man Materialien mit hoher Permeabilität, bei höheren Frequenzen Materialien mit niedrigem Widerstand.

Bei sehr hohen Frequenzen (Gigahertz) ist die Verwendung von kunststoffgefüllter Farbe oder anderen Materialien am besten geeignet.

Die Maxwell-Gleichungen von James Clerk Maxwell (1831–1879) beschreiben die Phänomene des Elektromagnetismus. Sie sind damit ein wichtiger Teil des modernen physikalischen Weltbildes.

Hysterese ist der Effekt, dass die Magnetisierung eines ferromagnetischen Materials nicht exakt proportional zum äußeren Magnetfeld verläuft und von der magnetischen Vorbehandlung des Materials abhängt.